What Are The Benefits Of Laser Cutting? from knay's blog

Before we move on to how laser cutters work, let's talk about the advantages of using this cutting-edge technology. First, laser cutting will produce your parts with the highest precision standards. Laser cutters are extremely accurate and capable of creating fine detail and intricate cuts, giving you a lot of design freedom. The laser machine cuts the material exactly the way you design it, with no room for error.

The laser cutting machine is fully automatic and saves a lot of production time. All the workers have to do is move materials. This fact results in low material waste and reduced production costs. The hands-free cutting machine is efficient and fast, making the manufacturing process simple and fast.

Last but not least, laser cutters are also capable of laser engraving, giving you more ways to develop projects and find the perfect solution for your production. With laser engraving, you can bring different depths and dimensions to your projects. Now let's talk about how the laser machine works in detail.

How exactly does a laser cutting machine work?

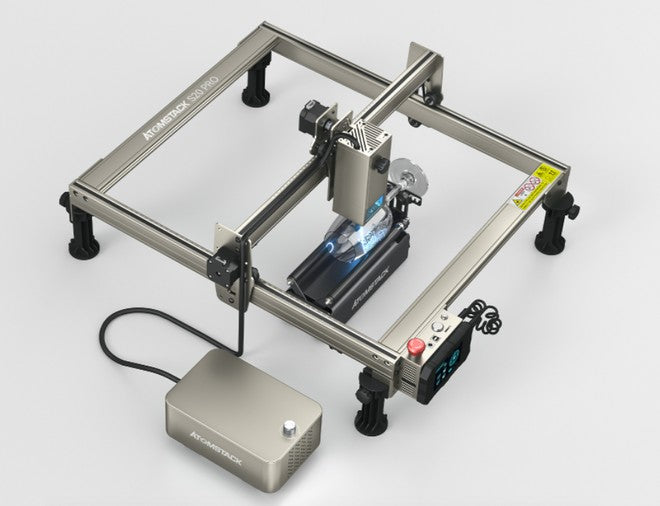

Laser cutting is a digital fabrication technique for 2D vector files. The laser cutter itself consists of a laser resonator that contains a gas mixture of crystals or glass fibers, depending on the cutting method. The cutting process begins when energy is applied to the mixture, and the laser is then focused through different mirror lenses.

Using a series of mirrors, the laser beam is directed towards the material through a nozzle. When it comes into contact with the surface, it evaporates the material into the shape of the vector file. The part of the material melted with the laser is called a cut and needs to be considered in your design. You can find all information about it on every page of our material.

A laser cutter is a powerful machine. We know this, which is why we provide you with the best materials to meet your production requirements. With our online laser cutting service, you can choose from 2 catalogs: European and American. We offer 5 different thicknesses of acrylic in 17 colors as well as stunning mirrored acrylic materials.

We also use our laser cutters to cut wood, such as plywood, in 5 different colour options and 3 thicknesses in both product catalogs and MDF in 7 colours in the European catalog. But we don't stop there, and to raise the bar, you can also produce your designs with our engineering thermoplastic POMs. Make sure you check out our top 10 best laser cutters post!

What can you do with laser cutting technology?

Laser cutting can produce some impressive projects. It can be used in a variety of industries, from mechanical engineering and more technology to decoration. A great example of a functional application of laser cutting is our exhibition table project in Lyon. We combine our 3D printing and laser cutting services. The finished product is durable, perfectly suited to our production needs and highly customized for exhibition needs.

This is not the only project where we use both techniques. Additive manufacturing and laser cutting are both great solutions for your production needs, and we have proven this with our drone project. Combining these two technologies allows us to have the ultimate design freedom and achieve lightweight structures.

Let the laser cutting machine change your production

Now that you understand how a laser cutter works and the advantages it offers you, you can know how beneficial it can be to your manufacturing process. Laser cutting gives you a lot of design freedom, a large selection of materials, and can be combined with other methods to give you the best results. We also offer laser engraving services for you!

When it comes to DIY laser engraver project ideas, you can use a variety of wood materials.

You can laser engrave different types of wood projects using ash, mahogany, maple, oak, pine, cedar, or veneer.

In most cases, you can't go wrong with MDF or plywood.

MDF is great for cutting or drilling and provides a shiny smooth finish.

On the other hand, plywood is more expensive and stronger than MDF. Since plywood is easy to bend, it is perfect for curved surfaces.

No matter what type of wood you use, follow the same process for wood laser engraver projects.

The Wall