What advantages and disadvantages do you believe are the most significant if you use a flat welding flange in your particular application and why do you believe they are the most significant from Phyllis Lucius's blog

Acid resistance of acid resistant asbestos plate makes it an attractive option as a general corrosive media for flat welding flanges, particularly in the automotive manufacturing industry, where it is used for flat welding flanges due to its acid resistance. To prevent leaks on high-pressure equipment and pipelines, standard precautions should include the use of metal gaskets of the lens type or other shapes on the equipment and pipelines. These gaskets should not be made of standard rubber but should instead be made of alternative materials such as copper or aluminum alloys as well as No. 10 steel or stainless steel, depending on the application. Because of their interaction, the high-pressure gasket and sealing surface have an extremely narrow touch width (line touch), and the processing finishes of both the sealing surface and the gasket (line touch) are exceptionally good.

There are several components that must be in place in order for the flat welded flangeto be constructed correctly. These components include:the application of a gasket for sealing purposes, which is composed of the following components:It is necessary to purchase sericite powder (2–6 parts), p-diisopropyldiphenylamine (5–10 parts), and carbon black N110 in order to complete this recipe, which can be found at your local pharmacy. Benzyltriphenylphosphorus chloride in a concentration of 3–6 parts per millionThe following components: 3–6 parts ech2-to-4 parts, flame retardant 2–4 parts ech2-to-4 parts flame retardant 2–4 parts ectee 2-to-6 parts ech2-to-4 parts, p-diisopropyldiphenylamine 5–10 parts, carbon black N110 parts3 The German Langsheng EPDM 9650 is composed of 80–85 parts, of which 2–5 parts are lubricant and the remaining parts are other components. The EPDM 9650 is manufactured by Langsheng, which is a family of companies based in Germany. It is produced by Langsheng, which is a German-based family of companies that manufactures EPDM 9650 rubber. It is manufactured by Langsheng, which is a German-based family of companies that specializes in the production of EPDM 9650 rubber products. In order to create a finished product, 3 8 parts casein plastic should be combined together with 3 8 parts methyl tritylketone oxime silane and 3 5 parts Rhine wax in a ratio of 3 8 parts casein plastic to 3 5 parts Rhine wax should be utilized.

The flat welding flange, which is attached to a vessel or pipeline with the help of a fillet weld, is an example of this type of attachment. When it is used, it can be found in a variety of different situations. If you look closely, you'll notice that flange was chosen at random for your use, and that's all there is to this whole thing. During the analysis phase of the design process, knowing whether a flange is integral or loose based on its type will be beneficial to the design process. As a result, when designing the straight cylinder section and its connection to the flange ring, it is critical to consider how to make this connection as strong and secure as possible because this is where the majority of failures can occur. By their structural design, flange rings can be divided into two categories. The first category includes those that have an internal neck, and the second category includes those that do not have an internal neck. The more common type of ring is a flange ring with a neck.

We will go into greater detail about the advantages of flat weld flanges in the sections that will follow this one.

For starters, the flat welding flange welding device is simple to operate and convenient to carry around. Furthermore, positioning this device in the desired location is a simple process with this device.

Abrasive materials are used in a wide variety of industries, including metallurgy, machine tools, the chemical industry, petroleum exploration and production (including water conservation), shipping, environmental protection (including coal), agricultural machinery (including food), boiler and pressure vessel construction (among others).

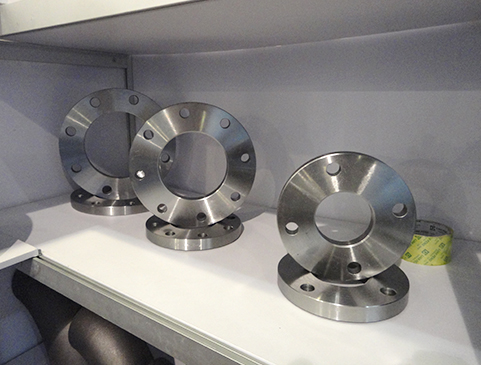

It is also possible to order a flat welding flange that has a flat and smooth appearance, which is a very appealing option to take into consideration. Typically used to connect carbon steel pipe, these flanges are available in a variety of sizes to accommodate a variety of pipe diameters.

One of the functions of a flat welding flange, among others, is that it can adhere to the pipeline while also performing the pipeline sealing function during this stage, which must be completed before the pipeline can be used in its intended application.

One disadvantage of flat-welding flanges is that they are unable to be joined together with other flanges.

It is not permitted to use insufficient rigidity with the intent of causing bodily injury as a result of the insufficient rigidity.

Its purpose, as described in paragraph 2, is to make navigating potholes in the road while traveling a little bit more bearable.

The Wall