Key Components of Blow Molding Machines: What You Need to Know from Jack Harry's blog

Blow molding is a complex process that involves various key components working together to create plastic products. Understanding the key components of blow molding machines is essential for anyone looking to delve into the manufacturing process.

The Extruder: A Critical Component

One of the most important components of a blow molding machine is the extruder. The extruder is where the raw materials, typically in the form of plastic pellets, are melted and formed into a homogenous molten mass. This molten plastic is then forced into a die head, which shapes the material into a hollow tube known as a parison.

The Mold: Shaping the Final Product

The parison is then transferred to the mold, which is another crucial component of the blow molding machine. The mold is what gives the final product its shape and size. Molds can come in various sizes and shapes, depending on the desired end product. It is important to ensure that the mold is properly designed and maintained to ensure the quality of the final product.

Mold Design and Construction

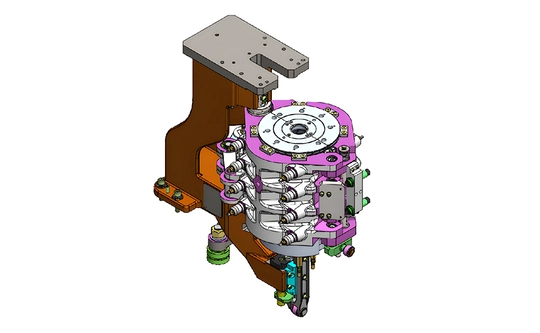

The mold is typically made up of two halves that come together to form the desired shape. These halves are often made of metal, such as aluminum or steel, that can withstand the pressure and heat of the blow molding process. The mold must be carefully designed to allow for the even distribution of the molten plastic and proper cooling to ensure a uniform product.

The Clamp Unit: Holding it All Together

Another key component of the blow molding machine is the clamp unit. The clamp unit is responsible for holding the mold halves together during the molding process. It applies the necessary pressure to ensure that the molten plastic flows evenly and that the final product is formed correctly.

The Blow Pin: Inflating the Parison

The blow pin is another essential component of the blow molding machine. The blow pin is used to inflate the parison inside the mold cavity, allowing it to take the shape of the mold. The blow pin must be carefully designed and positioned to ensure that the plastic is evenly distributed and that there are no defects in the final product.

The Cooling System: Solidifying the Plastic

The cooling system is also a critical component of the blow molding machine. After the molten plastic has been formed into the desired shape, it must be cooled quickly to solidify the material. The cooling system typically involves the use of air or water to extract heat from the mold and the plastic. Proper cooling is essential to ensure that the final product is of high quality and free from defects.

Conclusion

In conclusion, understanding the key components of Blow Molding Machine Supplier is essential for anyone looking to enter the manufacturing process. Components such as the extruder, mold, clamp unit, blow pin, and cooling system all play vital roles in creating plastic products through blow molding. By understanding how these components work together, manufacturers can ensure the quality and consistency of their products.

The Wall